Complete grid plants

1. warp knitting machine

2. coating machines

Each of these technical areas has its own approach, therefore, before each project, a concrete concept tailored to the customer is developed in order to ensure an effective and lasting solution.

We will be happy to send you detailed information on request. We are ready and able to design suitable solutions for you.

In order to receive a suitable business offer, we ask you to send us your detailed inquiry.

Field of application

- Medicine

- Automotive industry

- Military sphere

- Geotextiles

- Household

- Branch of industry

- Agricultural industry

- Sport

- Building and construction

- Textile material

- Packing

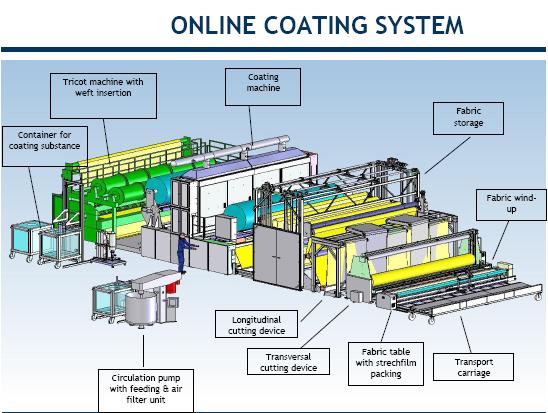

Coating system

- used for attached displacement fixing of the truss fabric (warp knitted fabric)

- the coating-material will be applied with the immersion or foulard procedure on the truss fabric (warp knitted fabric)

- subsequently with special infrared-heater tipped drying-duct, the coated product will be dried

- standard work width: 213” (=5410 mm)

- approx. manufacturing speed: 6m/min.

- total heating output: 300 kW

- approx. heating temperature at the commodity: 240° C

- the continuous agitation provide for a homogeneous distribution of the paste

- agitator at the paste trough is not essential

- easy cleaning during exchange the paste

- easy permeate of the scrim when starting the unit

- high accuracy in regard to the coating

- space-saving and vertical arrangement from the heating duct

- fast warm-up time and short cooling-off time by the drying duct

- 6 thyristor controlled heating zones, separately adjustable

- direct interfacing from face creation and coating

- winding and unwinding as additional intermediate stepp is not applicable

- minor stock and drying capacity

- more economic manufacturing

- dubbing with upstream production machine and following winder system

- fabric tension control by the pressure measurement bearing

- nominal value regulation between coating machine and winder

- easy control panel, which is handled by the menu

- recipe maintenance and process visualization